Go Plymouth Foam

Building Products

New Products and New Information

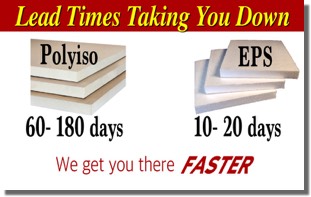

EPS (expanded polystyrene) is tailor-made for a variety of applications in construction including, but not limited to, residential and commercial building, roadway and foundation stabilization, and a wide range of other custom solutions. Geofoam blocks, used as ultra-lightweight fill below highways, parking lots and embankments take advantage of EPS’ properties of light weight, easy installation, durability and resistance to rot, mold and mildew. EPS is the most cost-effective insulation material, whose R-value does not decrease with age. When it comes to your next construction project, expect nothing less than perfect. Trust no one other than Plymouth Foam.

Concerns over the environment, the government has mandated new laws regarding the use of certain chemicals. How does this law affect the product? How does it affect what we use and specify? Can we be held liable if we don't understand and change our documents? Learn More

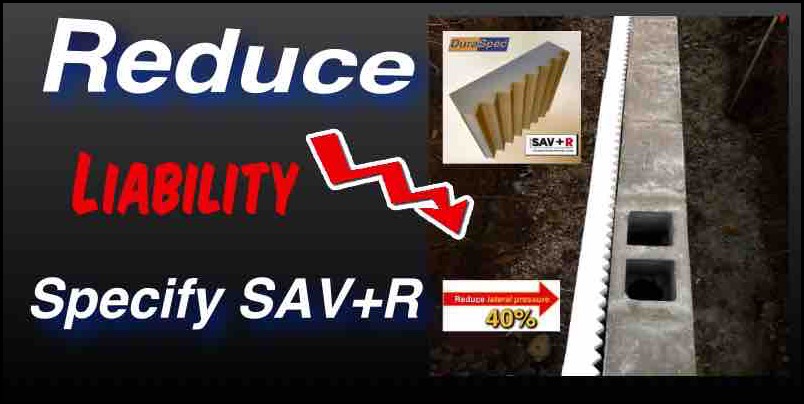

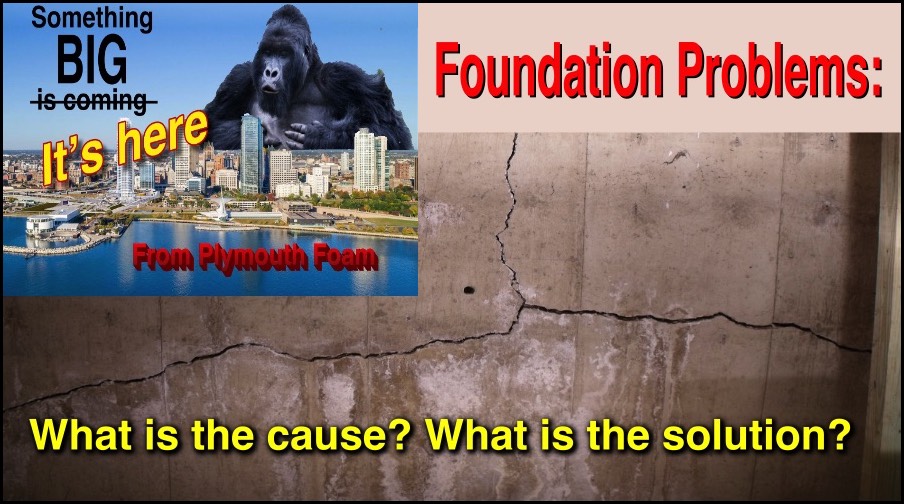

As an Architect or specifier there is large amount of risk designing a foundation. Specify the old systems in todays climate can be a recipe for disaster. Lawsuits claims over foundation are at $10 Billion per year. Why? Are soil conditions causing these additional issues? How do we account for lateral pressure - known or unknown? Learn More

Plymouth Foam has been honored with one of the best achievements that a manufacturer could ask for - Manufacturer of the Year. What secrets do they employee at their organization to win this honor. Find out.

For over 10 years, Plymouth Foam have been studying the cause and effects of foundation problems.

What are the causes? What are solutions?

What are the causes? What are solutions?

NEW Gold-Wall Video

Learn how to insulate the toughest masonry walls using Gold-Wall!

What makes Gold-Wall so useful?

What makes Gold-Wall so useful?

Is Roof Insulation's R-value guaranteed?

What Insulation is the BEST Value?

What Insulation is the BEST Value?

How will these new laws effect me?

How big of a deal is LTTR?

How big of a deal is LTTR?

Does insulation skins help or hurt R-value?

Is "Integral high density skins" important?

Is "Integral high density skins" important?

What can be down?

Do certain insulation work better with metal roofing?

Do certain insulation work better with metal roofing?

Go Plymouth Foam Building Products

New Plymouth Foam Video

"Building Solutions for Construction"

We bring Value through Innovative Energy Saving Solutions

Since the inception of Plymouth Foam in 1978, we have been the choice manufacturer and supplier of Expanded Polystyrene (EPS) Insulation for thousands of construction projects throughout the United States. Our DuraSpec™ line of products have been specially designed to enhance a building energy performance and durability.

DuraSpec Building Products offer a wide variety of rigid insulation for foundations, roofing, siding, walls, ceilings, slabs, cavities, building foundations, roads, retaining walls, cladding, below grade, utility protection, in-floor heating, footings, channels, panel cores as well as shaped and custom cut products. We manufacture Structural Insulated Panels (SIPs), Insulated Concrete Forms (ICFs), GeoFoam, Exterior Insulation Finish System (EIFS) products, Fan Fold, Tapered Insulation, Roofing Flute Fillers, laminated Products, Nailbase, Sill Seal, Concrete Expansion Joint, Garage Door Kits, Sun Room Panels, Gold-Wall, Neopor Insulation, Passive House products and many more energy efficient building products.

We service the entire United States, but specialize in the Midwest - Wisconsin, Minnesota, Ohio, Iowa, Illinois, Indiana, Michigan, Missouri, Pennsylvania and Kentucky.

The goal of Go Plymouth Foam is to educate the construction industry on quality energy efficient building products including new technology, techniques and tools.

DuraSpec Building Products offer a wide variety of rigid insulation for foundations, roofing, siding, walls, ceilings, slabs, cavities, building foundations, roads, retaining walls, cladding, below grade, utility protection, in-floor heating, footings, channels, panel cores as well as shaped and custom cut products. We manufacture Structural Insulated Panels (SIPs), Insulated Concrete Forms (ICFs), GeoFoam, Exterior Insulation Finish System (EIFS) products, Fan Fold, Tapered Insulation, Roofing Flute Fillers, laminated Products, Nailbase, Sill Seal, Concrete Expansion Joint, Garage Door Kits, Sun Room Panels, Gold-Wall, Neopor Insulation, Passive House products and many more energy efficient building products.

We service the entire United States, but specialize in the Midwest - Wisconsin, Minnesota, Ohio, Iowa, Illinois, Indiana, Michigan, Missouri, Pennsylvania and Kentucky.

The goal of Go Plymouth Foam is to educate the construction industry on quality energy efficient building products including new technology, techniques and tools.

There are many ways to visit with a Rep from Plymouth Foam. We want to help.

Building Solutions Using Expanded Polystyrene

Expanded Polystyrene (EPS) has been long used as a mainstream rigid insulation material, and is highly regarded for its energy efficiency. It is the only architectural insulation material with an R-value that will not decrease with age. Additionally, EPS is lightweight, easy to install, durable, and resistant to rotting, mold and mildew.

New research into EPS has busted all of the myths and made using this as a building product even more desired. Engineered ESP or sometime known as Architectural EPS, has been proven through various studies to be strong, have a more consistent R-value, be environmentally friendly and green, absorb less and expel more moisture and have better long-term characteristics.

EPS is also the most cost effective rigid insulation in the market. In fact, EPS is the best value by providing the lowest cost per R-value inch. Don’t just take our word for it, Value Engineering will tell you the cost value just like it saved this contractor 1000’s of dollars on his construction project. Our foam insulation has been saving customers and building owners money compared to other insulation products and have help them save money by reducing their utility cost.

Today, we hear a lot about for the need for sustainability, environmentally friendly and green. Thermal insulation is the single largest factor which influences the energy performance of a building. EPS has been proven to hold its thermal properties longer than any other insulation, even when moisture is present. EPS cell structure is 98% air, which makes it easy to transport and the low weight saves fuel cost during transportation. Not only is the product 100% recyclable but our plant recycles waste and cut off inside the factory and reuses the waste into new products. In fact, EPS is one of the most recycled plastics in the world.

New research into EPS has busted all of the myths and made using this as a building product even more desired. Engineered ESP or sometime known as Architectural EPS, has been proven through various studies to be strong, have a more consistent R-value, be environmentally friendly and green, absorb less and expel more moisture and have better long-term characteristics.

EPS is also the most cost effective rigid insulation in the market. In fact, EPS is the best value by providing the lowest cost per R-value inch. Don’t just take our word for it, Value Engineering will tell you the cost value just like it saved this contractor 1000’s of dollars on his construction project. Our foam insulation has been saving customers and building owners money compared to other insulation products and have help them save money by reducing their utility cost.

Today, we hear a lot about for the need for sustainability, environmentally friendly and green. Thermal insulation is the single largest factor which influences the energy performance of a building. EPS has been proven to hold its thermal properties longer than any other insulation, even when moisture is present. EPS cell structure is 98% air, which makes it easy to transport and the low weight saves fuel cost during transportation. Not only is the product 100% recyclable but our plant recycles waste and cut off inside the factory and reuses the waste into new products. In fact, EPS is one of the most recycled plastics in the world.